It’s the white gold that gives ski resorts their essence, but these days, snow is an increasingly precious commodity. Whether it’s falling from the sky in silent, fluffy flakes or being pumped out of the now ubiquitous snow cannons lining the ski runs, resorts rely on the white stuff to maintain a viable business.

But with climate change affecting snow reliability in the mountains, particularly in lower altitude resorts, more and more venues are employing a third method to supplement coverage and attract enough visitors to open the lifts at the start of the season.

Snow farming is the practice of stockpiling snow from the end of one season, collecting and storing it under a vast tent of insulated mats, then spreading it out again next winter – like rolling up the red carpet after the Oscars ready for next year, then spreading it out again the following winter.

Innovative Finland strikes again

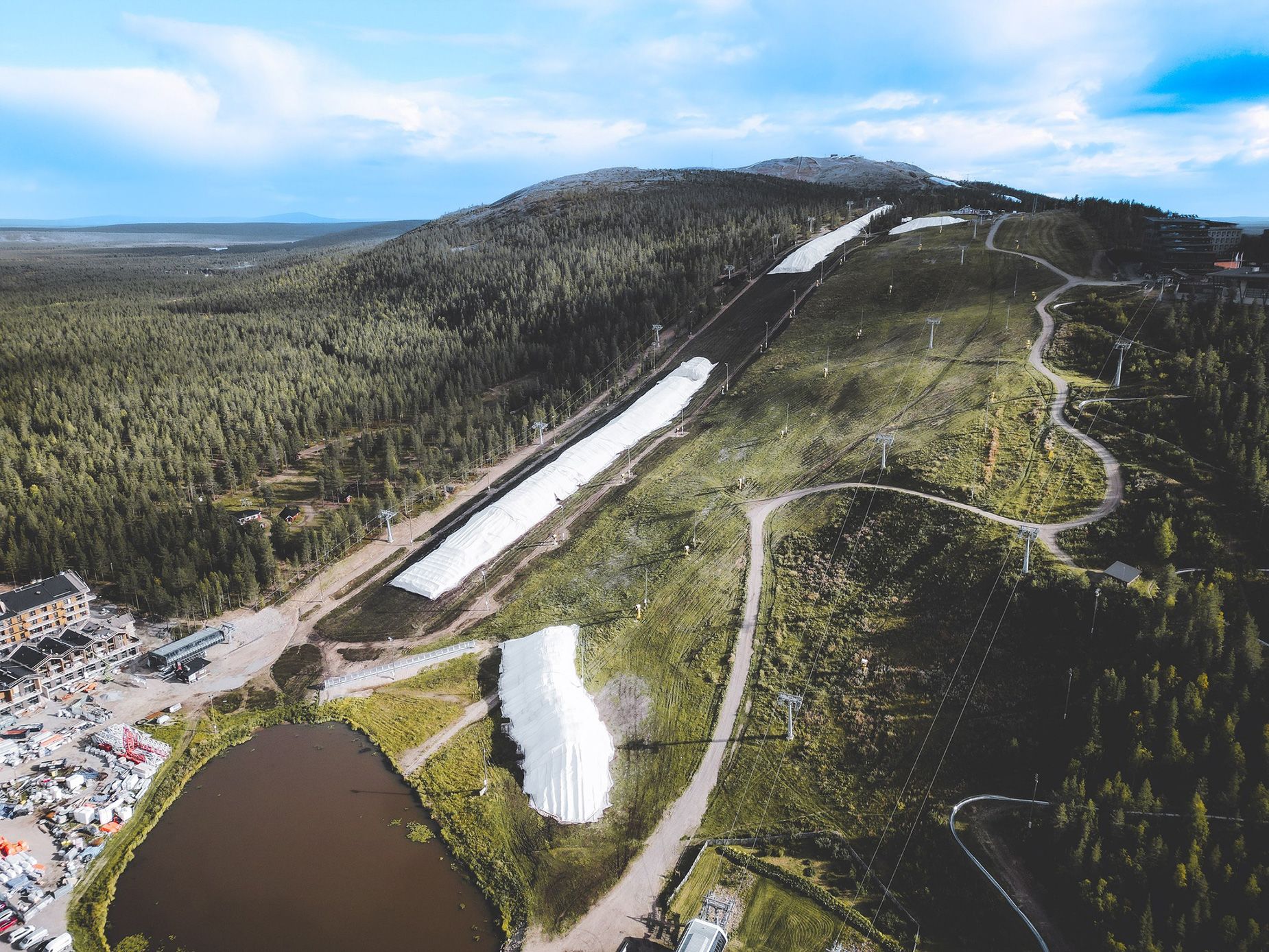

One place this seemingly straightforward approach is being pioneered is the resort of Levi in the far north of Finland.

There, they ensure the resort can open in early October, and virtually guarantee the early-season World Cup ski races can go ahead in November, by using farmed snow to lay down a base layer on certain runs without needing to rely on nature’s bounty.

Nor do they have to operate the snow cannons – which force out water and compressed air to fall as snow crystals – in less-than optimal conditions, leading to huge savings in electricity and water.

“Of course, snow is the most critical element in this skiing business, it’s our gold so we save the gold by storing it and using the snow to help start the season,” said Marko Mustonen, commercial director of Levi.

“Sometimes it’s tough, the seasons aren’t always excellent and snow in winter arrives at different times.

“When winter starts, one day it is -5 C (-23 F), one day it is raining, but we don’t need to worry about these types of conditions because we have a nice, certain layer of snow already.

“We can then use the automatic [snow cannon] systems to make skiing as good as possible after that. If we make snow in -10C rather than -1C or zero C it is almost 10 times better efficiency.”

Learning curve

In Levi, there are nine strategically placed storage areas for the stockpiled snow, which this year amounted to 200,000 cubic meters. All the snow mounds are covered with 70 milimeter (2.8-inch) -thick insulated mats, made of Finnfoam used in the construction industry, and topped with a waterproof sheet.

“At the moment under our mats in the north part of Finland, the melting rate is under 13%, which is pretty good,” said Kalle Palander, a retired Finnish ski racing champion and sales director for Snow Secure, the company behind the insulation.

“And every year we learn more.”

What began on a small scale in 2016 to combat repeated cancellations of the World Cup slalom races on the Levi Black slope has grown into a wider operation to prepare a number of ski runs for visitors, including the new showpiece Levi Glacier run, as well as cross-country tracks, some of which can be preserved under a layer of sawdust or woodchips.

“It’s important, economically, for the ski resort,” adds Mustonen. “It means when we get the first lift opened, we get people here and we are alive.”

Snow farming is just a small part of Levi’s overall snow production and management, but it has contributed to the resort’s commitment to reducing its carbon emissions, on the way to becoming net zero carbon “by 2050 or as soon as possible.”

Levi, which has used renewable electricity since 2020, has also switched its fleet of snow grooming machines to biofuel for the 2023-24 season, making the snow farming even a greener alternative to fossil fuels.

Olympic solution

Machine-made snow has been a long-time ingredient in producing top-level ski racing tracks, and skiing on farmed snow from last year is equally as good as the fresh stuff, says Mustonen.

“You wouldn’t find any difference on it, and it’s maybe even holding better, it’s very good for skiing,” he said.

Even back in 2014, organizers of the Sochi Winter Olympics in Russia were storing about 800,000 cubic metres of snow to supplement the natural and man-made supplies to ensure the alpine events could go ahead, mindful of the unpredictable conditions at the Rosa Khutor venue and the lack of snow at Vancouver 2010. A similar process was repeated at the 2018 Pyeongchang Games and Beijing 2022 Winter Olympics.

In Cervinia in Italy this summer, five great mounds covered in white matting stored snow to lay down a base for the new World Cup downhill ski run, starting high up on the Theodul Glacier above Zermatt in Switzerland before swooping across the border and plunging down to a finish line on the Italian side, overseen by the imposing pyramid of the Matterhorn.

Austria’s Kitzbuhel, home of the infamous Hahnenkamm downhill ski race, has been snow farming since 2015 and uses it to prepare piste No. 71 (Resterkogel) for early-season skiing. The snow depot is sited directly on the sheltered piste to limit transportation and contains about 30,000 cubic metres of snow, stored under insulated covers.

In Davos in Switzerland, snow farming is used to create a four-kilometer (2.5-mile) cross-country ski trail that is open by the end of October. About 20,000 cubic meters of machine-made snow – which is harder and more compact than natural snow and so better for conserving – is created the previous December or January when the weather is at its coldest and is covered in wood chippings and then spread out in the fall, with about 80% remaining. The track is open to professionals and amateurs alike with bookable time slots.

“It’s very popular for professional cross-country skiers, and we get skiers from maybe 12 nations coming here for early training,” said Samuel Rosenast, head of communications for Davos.

Saving glaciers

In North America, resorts including Banff Sunshine in Canada and Arapahoe Basin in Colorado trap wind-blown snow with a network of fences for redistribution to other parts of the ski area but they are still using that year’s supply which melts back into the watershed in summer.

Another Swiss resort, Laax, uses snow farming to protect its endangered Vorab Glacier, which experts predict could disappear in the next 30-35 years if manmade global warming continues at the same rate. Snow is redistributed onto the glacier in May and covered in insulation until September to slow down the melting of the ice and to preserve the foundations of the drag lift which serves the ski runs.

“Covering parts of the glacier and pushing a lot of snow together in spring allows us to open the glacier for winter sports a little earlier in autumn, as we don’t need the same amount of new snow coming from the sky,” said a spokesperson for Laax.

In southeast Switzerland, glaciologists Felix Keller and Johannes Oerlemans found through a 2017 pilot study and subsequent computer modeling that covering part of the fast-retreating Morteratsch Glacier with machine-made snow could slow down its rate of melting and could even lead to growth of the glacier in 10 years in the right conditions.

The idea is that a lattice of sprinklers employing similar technology to snow cannons is placed over one square kilometer of the most melt-prone ice and constantly sprayed with sustainably produced artificial snow.

The project, known as MortAlive, was launched in February 2021 and is in the fund-raising and development stage, but critics say it is a sticking-plaster solution when the real fix is to halt human-induced climate change.

— CutC by cnn.com